Irene and I are not people who exercise much. Yet over the years we have collected a stable of expensive exercise equipment, the primary purpose of which is to collect dust.

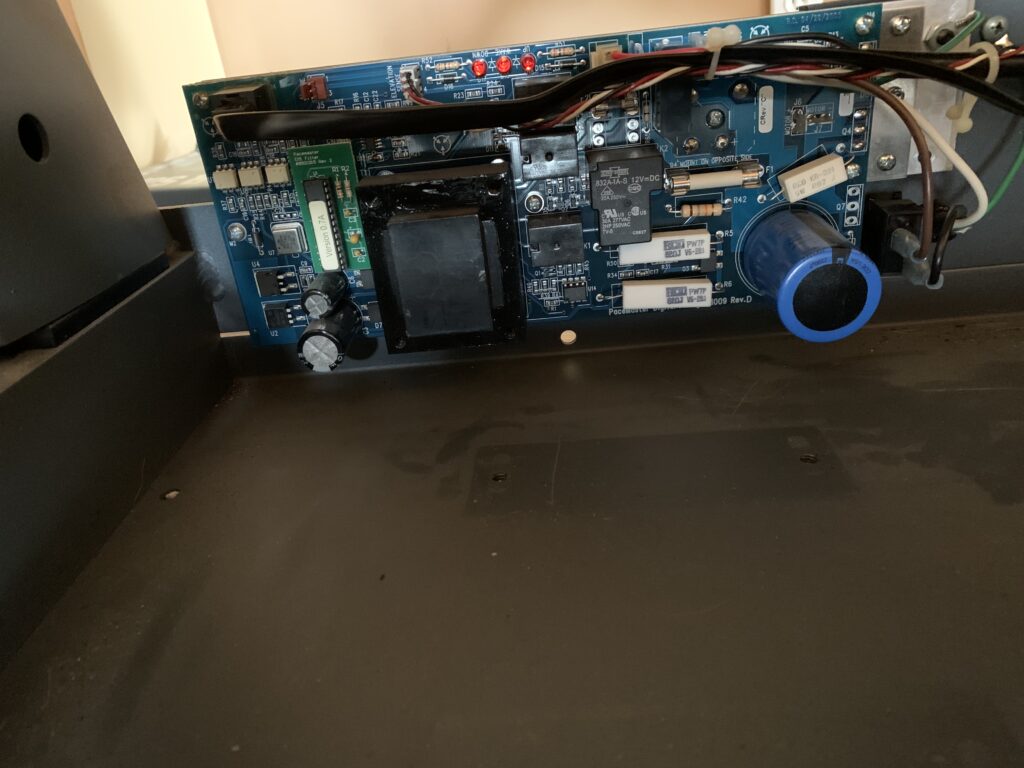

The only machine that we use somewhat regularly is the treadmill. I would guess that this very expensive PaceMaster Pro VR has about 1,000 km of mostly walking on it over the 20 years or so we’ve owned it. I’ve been using it again fairly regularly for the past six months to avoid becoming completely immobile.

The treadmill stopped working about a month ago: attempting to start it produced a loud beeping and an error code 425 message on the display. I have made it work again. This is the story of that adventure.

Debugging

My Google-fu led me to a website that has some diagnostic information about the PaceMaster error 425 code. The guidance suggests checking the 20 amp fuse on the motor control logic board and separately testing the motor itself.

I also found references to the resettable fuse on the back of the machine and the usual guidance to try unplugging and plugging it back in. After completing the ‘easy’ checks I tested the ceramic 20 amp fuse with a multimeter and confirmed it was passing current without resistance and so it was still ‘good’.

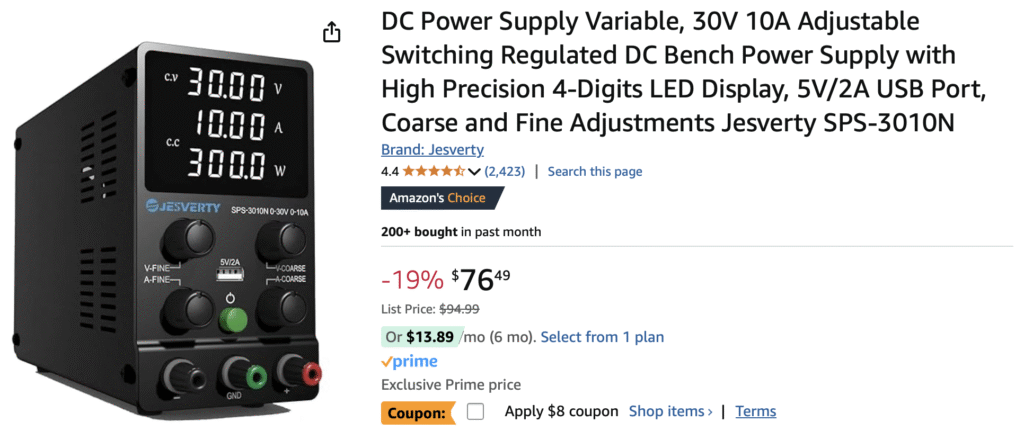

My final test was of the motor itself. I didn’t like the idea of using the battery from one of my power tools so first I purchased an inexpensive variable voltage/current DC power supply for about $80. I set the voltage to 18 volts and current to 2 amps to ‘match’ a typical power tool battery and connected it to the motor: nothing happened. This lack of a response from the motor made it the most likely culprit in the failure.

Replacing the motor

Ordering

PaceMaster went out of business in about 2011, so I couldn’t get a motor directly from them. I was, however, able to find a complete parts list for the PaceMaster Pro Platinum VR treadmill via a company called “PaceMaster Service.” The parts list gave me the correct part number for the motor assembly: DBBDRMTR. Strangely “PaceMaster Service” didn’t have a simple web store interface, so I looked elsewhere for the motor.

I turned once again to Google and, armed with the part number, found a company that sells the assembly: Treadmill Doctor. The motor wasn’t too expensive, but the real cost including shipping, duty, and currency exchange basically doubled the cost. And of course I couldn’t be 100% sure that it would work until the money was already spent. Fingers firmly crossed, I clicked the purchase link.

Installing

Several weeks later I had the new motor, all 40 pounds or so of it. Before doing anything I repeated the test with the power supply: the new motor spun! This felt like a win, so I proceeded with the replacement process.

Treadmill Doctor’s web site provided a helpful guide to the replacement. In essence, the process involves:

- removing the original motor from the treadmill

- removing the bracket and speed sensor wheel from the old motor

- attaching these re-used parts and the (supplied) speed sensor to the new motor

- installing the new motor in the treadmill

Completing the install took about two hours, maybe closer to three as I struggled a bit getting at some of the bolts. But there were no real problems in the process, and the treadmill started up without a hitch after I was done.

More captive steps

I half-heartedly tested the treadmill by walking on it for about five minutes after completing the motor replacement. Everything seems to be working again- speed and incline adjustment are both working normally. I even jumped off and cranked the motor up to its maximum for a bit: 12.5 miles per hour is a speed I’ll normally never hit while actually using the machine, but it is nice to know it works again.

I’m optimistic that the torture machine will be good for another decade or two of slow, low-energy exercising even if I’m not.

Kelly buying an ‘inexpensive’ $80 power supply to save a $40 battery 😀

You can get all sorts of info and parts online which is a Goodsend for fo it yourself repair. Unfortunately it also leads to things like me having to deal with contractors using second hand scavenged nurse call parts bought on e-bay that come out of some hurricane damaged facility in the states.

Well, my batteries are for a Dewalt, and they are about $120, so… 😉 But really, it was an excuse to get a proper variable power supply. I’ve only had use for one a handful of times in my life, but now I have one: huzzah!

Buying stuff on E-Bay is always a bit of a crapshoot. I’ve had a bit of good luck with it by being very careful, but… if I can find new parts (as I did in this case) I feel safer. E-bay is a “Hive of scum and villainy….” to quote a particular Jedi. There is always someone claiming they did the Kessel run in 12 parsecs…

My biggest worry was that I’d get the motor and find out that it wasn’t really the problem… or the only problem. It still strikes me as a bit odd that a DC electric motor would die so completely after what is truly light usage. But then again- it is 20 years old, which is a long time even with minimal use.